In addition to the die-cutting method, precision of die-cutting equipment, die-cutting tools and self-adhesive materials, the die-cutting quality of self-adhesive label stickers is also affected by factors such as the proficiency of the operator, the processing environment, and static electricity. related.

01. Self-adhesive surface material

In the die-cutting process, the die-cutting knife must cut off the self-adhesive surface material and adhesive layer to complete the die-cutting process. Therefore, the self-adhesive surface material is an important factor affecting the quality of die-cutting, and the suitable die cutter should be selected according to the self-adhesive surface material. General suppliers provide two kinds of die cutters: die cutters without hardness treatment and die cutters with hardness treatment for commercial printing. When die-cutting paper stickers, you can choose die cutters without hardness treatment. ; If it is a film type self-adhesive label, you must choose a die-cutting knife that has undergone hardness treatment to ensure the quality of die-cutting.

02. Adhesive

Adhesives used in self-adhesive materials are divided into acrylic water-based latex and rubber-based hot melt adhesives. Due to the low cohesion of acrylic water-based latex, it is easier for die-cutting evaluation, and there are no special requirements for die-cutting tools and die-cutting environment, and the quality of die-cutting can be well guaranteed. The cohesive force between hot melt adhesive molecules is relatively large, and the requirements for die cutting tools and environment are relatively strict. The die cutter must completely cut off the adhesive layer to ensure normal waste discharge enterprises, otherwise the label will be removed from the bottom paper take away. In addition, hot-melt adhesives have higher requirements on the processing environment, because hot-melt adhesives are less active at low temperatures, and the bonding force between the self-adhesive surface material and the bottom paper is too small during waste discharge, which may easily cause “flying marks” .

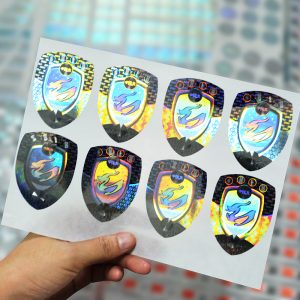

Sticker sticker

03. Self-adhesive bottom paper

The bottom paper has two functions in the self-adhesive material: the base layer of the release material and the support material of the face material. Regardless of whether the flat die-cutting method or the circular die-cutting method is used for development, a very important prerequisite for ensuring the quality of die-cutting is to ensure the flatness of the bottom paper. Especially when the circular die cutting method is adopted, because the thickness of the blade of the die cutter is determined by the thickness of the backing paper, if the backing paper is uneven and the thickness is uneven, the blade will cut through the backing paper or not cut through the surface material. Waste disposal brings difficulties. It is generally required that the self-adhesive bottom paper has good flatness and uniform thickness, so as to ensure accurate die-cutting.

04. Die cutting method

At present, there are two main die-cutting methods used in self-adhesive labels: flat die-cutting and round die-cutting. The flat die-cutting method uses the die-cutting knife and the bottom plate to press together, and the sticker surface material is cut under the action of pressure. In order to ensure that the pressure is balanced throughout the die-cutting, cumbersome pressure adjustments are required. The die-cutting accuracy of self-adhesive labels is generally required to be about 5μm HP. However, due to its own limitations, the flat die-cutting process usually cannot meet the high-precision die-cutting, which often results in partial surface material cutting or bottom paper cutting. problem. Moreover, flat die-cutting is not suitable for die-cutting large-area self-adhesive labels.

Sticker sticker

The circular die-cutting method is a relatively advanced processing technology, which has the obvious advantages of high precision and high processing efficiency. The most basic principle is to determine the height of the blade according to the thickness of the bottom paper, so as to control the stability of the die-cutting quality. Because the die-cutting knife of the circular die-cutting method is in line contact with the bottom roller, as long as the pressure at two points is controlled, the consistency of the die-cutting pressure can be maintained, so the die-cutting accuracy is very high.

05. Other factors

In the entire die-cutting process, the quality of die-cutting is also related to the image processing of factors such as the technical level of the operator, the production environment of the workshop, and the accuracy of the die-cutting machine.