What are the methods for making self-adhesive labels?

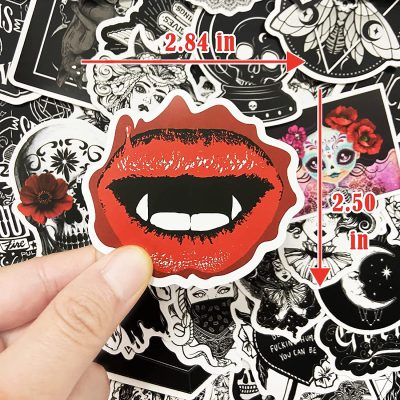

Self-adhesive labels are also called self-adhesive labels, prompt stickers, instant stickers, pressure-sensitive paper, etc. They are made of paper, film, or special materials as fabric, coated with adhesive on the back and coated with silicon-based paper as the protective paper. Composite materials are processed into finished labels after printing and die-cutting. In application, it can…